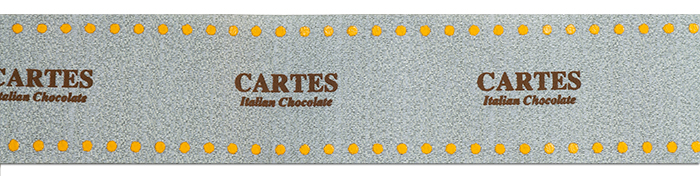

SILK-SCREEN PRINTING AND OVERPRINTING MACHINE FOR RIBBONS

The machine SN161 is specifically designed to perform high quality silk-screen printing on flexible materials in roll such as ribbons and narrow fabrics with all kind of IR silk-screen inks. The preparation of new jobs is easy and fast and makes this machine suitable to fulfil short and long runs. The reliability of the materials used to build this machine and the quality of the

electronic components allows working at the highest speed with every kind of silk-screen inks, even puffed. The frame is positioned lengthwise in order to gain speed during the fourth movement of the ribbon, which comes out from the printing area while the spatula returns to its original position. At the output, an IR oven allows to perfectly dry any kind of printing.

CONFIGURATION

- 4 unwinding shafts at the input;

- Set composed of 4 photocells;

- 1 printing frame support of 800 x 400 mm (31 1/2 x 15 3/4) in, other dimensions are available on request.

- The frame size is suitable either for small and big printing formats;

- Web feeding made by conveyor belt, solvent and acid resistant, operated by stepper motor;

- The printing unit can lift up for a fast cleaning;

- Printing length adjustable by keyboard;

- Touch screen control panel;

- Squeegee and spatula position adjustable both crosswise and in height by means of micrometric thread screws;

- The spatula/squeegee unit can lift up independently from the printing unit;

- Spatula stroke adjustable by servo motor according to the printing length (max. 800 mm – 31 1/2 in);

- Adjustable material output speed.

| Technical Data | |

|---|---|

| MAXIMUM NUMBER OF RIBBONS TO BE PRINTED | 4 |

| PRINTING FRAME EXTERNAL DIMENSIONS | (800 x 400) mm - (31 1/2 x 15 3/4) |

| PRINTING AREA | (520 x 200) mm - (20 15/32 x 7 7/8) in |

| PRODUCTIVITY | up to 1,000 cycles / hour |

| PRODUCTIVITY WITH 4 RIBBONS | up to 2,000 meters (2,187 yd) / hour |

| CONVEYOR BELT SPEED | Adjustable up to 23 meters (25 yd) / minute |

| POWER SUPPLY | 400 V three-phase - 50 / 60 Hz |

| CONSUMPTION | 4 kW |

| COMPRESSED AIR | minimum 6 Bar (87 psi) |

| DIMENSIONS | (2830 x 1110 x 1850 h) mm |

| WEIGHT | 830 kg |